SEDISONIC™ - Application to printer ink formulation

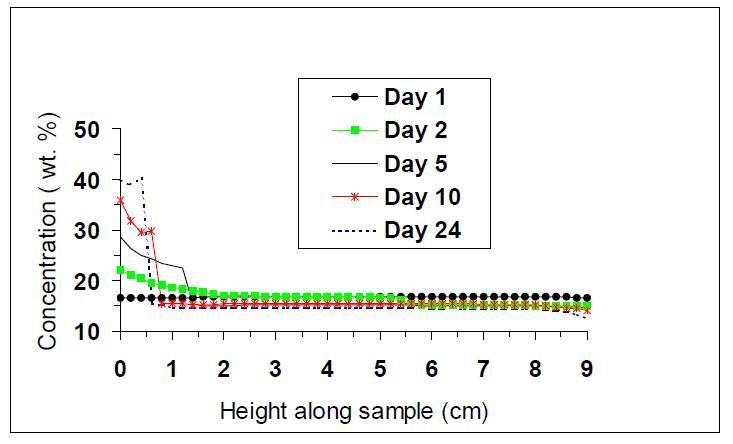

One main use of the ultrasonic method is the measurement of stability in different product formulations. This figure is an example of measurements on an unstable suspension, where time-of-flight (TOF) readings of an ink suspension were recorded for a manufacturer of printing ink. Repeated measurements were taken of the sample after the indicated number of days, up to 24 days. For each measurement, the sample was placed in a water bath with the Scanning mechanism and allowed to equilibrate to 35C. After testing, the sample was returned to the shelf to settle further.

On the first day, the concentration was 16.5% all along the container. The first sign of settling was detected after just one day, with a 2.0 cm build-up of solids at the bottom of the sample. After five days, a sharp interface in concentration began to appear about 1.3 cm from the bottom of the container. Neither this interface nor the lower concentration at the top could be observed by the human eye. After 24 days, significant settling occurred, and the concentration at the bottom reached about 40%, with the top dropping to 11%. Four months later the settling was pronounced, with the bottom concentration at 50% and the top at 3%. The formation of the interface and its movement was governed by the particle size and viscosity of the slurry, with progressive movement of this interface toward the bottom of the container. The gradual movement of this interface is key to understanding the sedimentation characteristics of the suspension. These ultrasonic measurements are helping the manufacturer optimize the formulation of the printing ink.